EZ lift pins

EZ lift pins

The Lane EZ Lift Pin is the original manhole lift pin. Developed over 20 years ago, the Lane EZ Lift Pin offers the precaster and contractor an ideal and versatile lifting product that is also cost effective.

learn more:

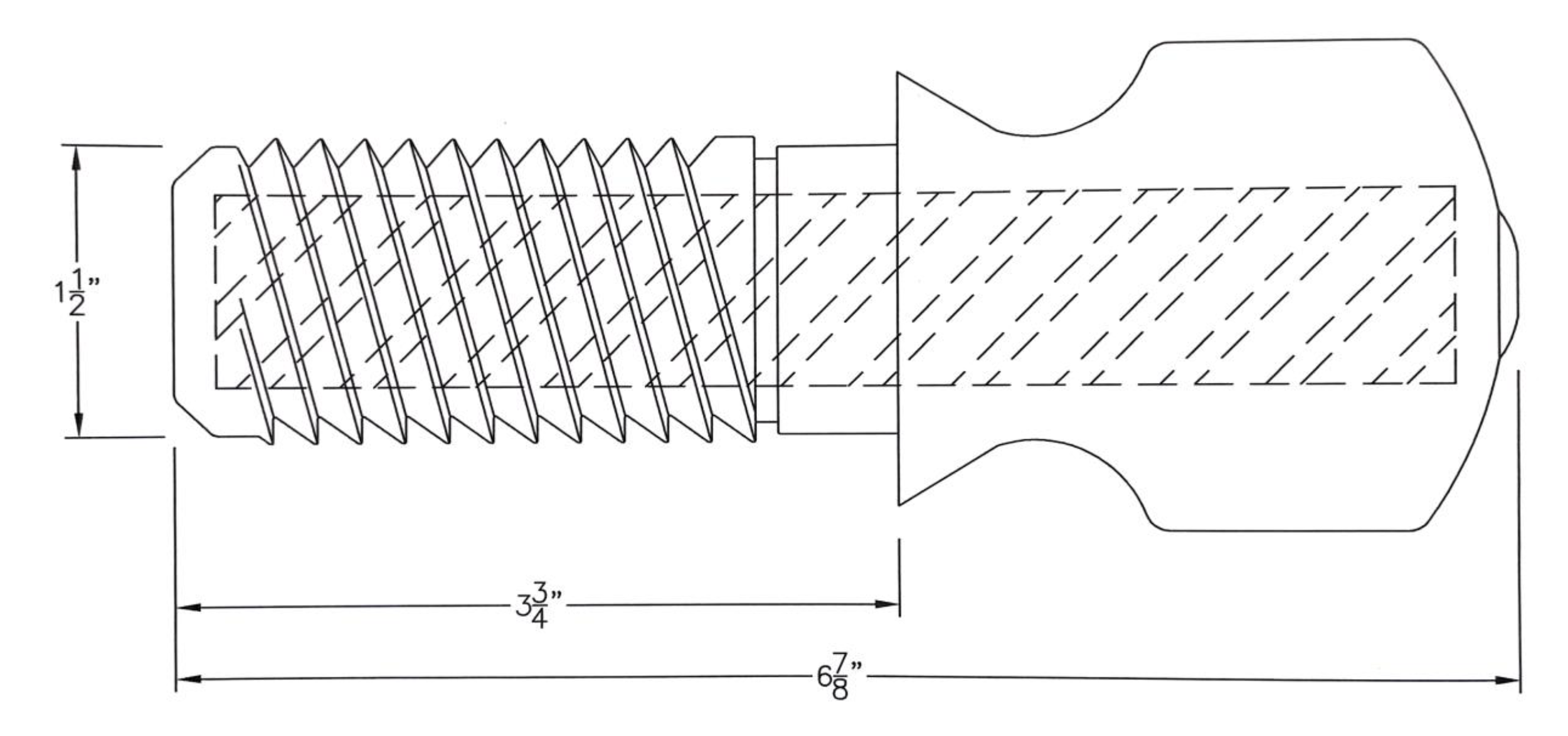

Each pin is injection molded polypropylene around a 1-1/8” diameter ASTM A-615 Grade 60 reinforcing bar. The polypropylene material conforms to ASTM D-4101 specifications.

LOAD CAPACITY:

The working load limit is 4,000 lbs. per pin

* Ultimate load is four times the working load.

additional EZ lift pin parts:

Threaded inserts

The one-piece Lane Threaded Inserts are precisely manufactured to fit the Lane EZ Lift Pin.

These heavy-constructed Threaded Inserts are a one-piece injection molded part. This insures a water and vacuum tight fit.

The outside rings eliminate infiltration or exfiltration along the outside of the part.

Suitable for both wet and dry cast operations.

Be assured of a positive fit each and every time.

The Lane Threaded Inserts are to only be used with the original Lane EZ Lift Pins.

Threaded Insert Holder

The Lane Threaded Insert Holder was designed to allow for easy installation of the Threaded Insert in both wet and dry cast operations from outside the jacket.

INstalation instructions:

Installation requires drilling a 2-1/2” dia. hole in the jacket. Simply weld the machined bushing centered over the drilled hole with the handle at the 5 o’clock position.

Screw the Threaded Insert on to the Insert Holder and slide through the bushing. Rotate the handle and lock into place.

To remove the Insert Holder, simply lift up on the handle and unscrew.

Threaded Insert Holder Magnets

The Threaded Insert Magnets are the perfect solution where insert location changes depending on product. Simply locate the position where the Insert is required on your form and the magnet securely holds the Insert during the pour.

Wet Cast Forming Pin

The Wet Cast Forming Pins are designed to create perfectly formed holes for the Lane EZ Lift Pins. Simply weld the bushing to the outside of the form and insert the Forming Pin.

Installation instructions

Drill two 1-1/2” dia. holes in the wall of the form directly apart from each other. Tack weld steel bushing to outside of form and insert pin.

Simply tap the pin’s handle to rotate and remove. Keep the pin clean to assure consistent hole sizes.

Once the concrete has cured to at least a 3,000 PSI compression strength, the EZ Lift Pins can be driven in with a 6 –8 lb. sledge hammer.

EZ lift pin installation tool

Installing the Lane EZ Lift Pin into the threaded insert is now a snap with the new installation tool.

Use any 20V with 1/2” drive cordless drill. Line up the pins inside the tool with the slots on the

EZ Lift Pin and you are ready to install your Pins!